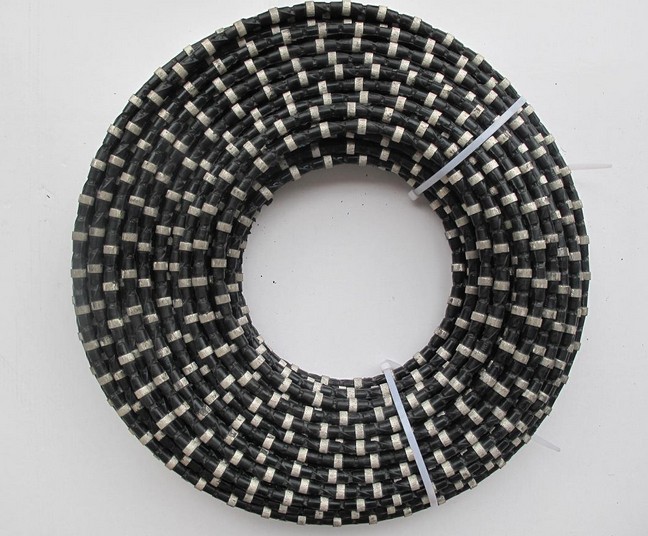

Diamond Wire Saws for Granite Quarry Cutting

Diamond Wire Saw for Granite Quarry Cutting is a revolution for stone quarrying, which is highly efficiency in exploitation, safety and environmental friendly when operation. With this technology, the quarrying will have a high yield of good blocking and the size of blocking will be large. With the promotion of Diamond Wire Saws, the situation of high consumption of resource, low output, small size of block, danger, pollution can be hugely improved.

Diamond wire saws are widely used for granite quarries. The main specialties of diamond wire-saws are :

· To be able to used for great area granite quarries cutting;

· To get high percentage of forming dimension stone;

· High manufacture efficiency;

· Safety, low-noise, no-dust and friendly surroundings;

· Low cutting cost.

|

Diameter

|

Code No.

|

Fixing Type

|

Beads No.

pcs/M

|

Granite Hardness

|

Linear speed (m/s)

|

Cutting speed (mm/min)

|

Wire life(㎡/m)

|

|

Ф11.5mm

|

DWSGQ01 |

Rubber

|

40pcs

|

Class 1-2

Class 3-4

Class 5

|

26-30

22-26

18-22

|

5-7

2-4

1-3

|

12-20

8-12

4-8

|

| DWSGQ02 |

Rubber+Spring |

| Ф11.0mm |

DWSGQ03 |

Rubber

|

| DWSGQ04 |

Rubber+Spring |

The technical information is only for reference.

We also can:

· Change the diameter according to customer‘s request.

· Offer diamond diamond beads with different hardness (HRB95-105).

· Offer diamond beads with different length.

· We develop special rubber and the technology of vulcanization, make sure the diamond wire can work in most hard-working conditions.

Recommendations:

For granite quarrying, the cables are in general fitting by injection of vulcanized rubber, the advantage is better adheres to the beads and support cable, which protect it better from the action of abrasive pastes. The rubber wire easily withstands increases in temperature caused by badly controlled water spraying is power 11-75KW. The water spraying between 25-50 L/min according to the cut dimension.

Other specifications are available upon customer‘s requirements.

|